Long gone are the days when companies could focus solely on the standard bottom line to drive and measure their success. Today, with pressure mounting from customers, regulators, and financiers, companies must integrate environmental and social sustainability across their entire operations and supply chain. Although there is little doubt about the urgency of developing an ESG strategy, the way to do so and the ability to track progress toward identified targets can still be challenging.

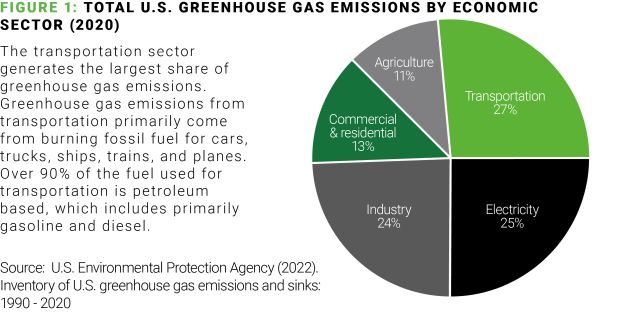

The Transportation and Logistics (T&L) industry is no exception to this. Despite historically being one of the most significant contributors to greenhouse gas emissions (Figure 1), companies in this space have lagged in their sustainability efforts. However, with tightening scrutiny through laws such as the forthcoming SEC climate-related rule and the EU's Corporate Sustainability Reporting Directive (CSRD), companies can no longer afford to only be reactionary to legal requirements. Rather, to stay ahead of the curve and enhance value creation, executives need to proactively commit to measuring and reporting their environmental and social performance in anticipation of an inevitable wave of ESG regulations and opportunities.

How can executives drive sustainability while increasing the efficiency of their operations?

While rapidly growing interest and advancements in technological solutions for ESG impact are presenting new avenues for executives to choose from every day, this article outlines four initiatives to get started.

One: Establish visibility into your organization's carbon emissions (Scopes 1, 2, and 3)

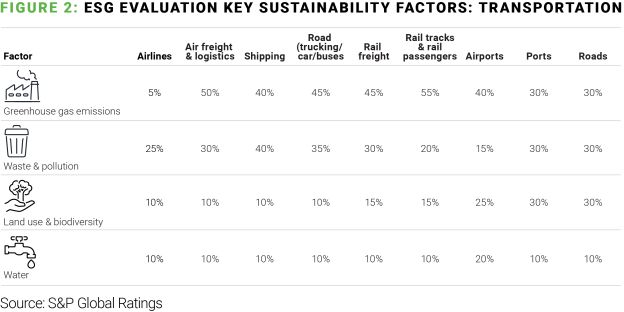

To start, it is pivotal for T&L companies to conduct a baseline assessment of carbon emissions directly attributable to their own operations (Scopes 1 and 2) and indirectly from suppliers and other entities in their value chain (Scope 3). Note, that across business models, GHG emissions stand out as the most significant environmental factor (see Figure 2). Thus, focusing on this allows companies to address a large (if not the largest) chunk of their total environmental impact.

To conduct a baseline assessment of carbon emissions, companies must map their supply chain and develop a GHG monitoring system through mechanisms such as freight audit and energy consumption analysis. Ensuring consistent access to such data serves as the foundation for actively monitoring and reporting ESG progress. Additionally, leveraging ESG standards such as the recently released International Sustainability Standards Board (ISSB) standards1, IFRS S1 (general requirements) and IFRS S2 (climate disclosure requirements) and benchmark data (readily available through EPA) paired with data analytics not only enables greater transparency and visibility into the supply chain but also allows for identification of reduction levers and targets in accordance with industry and competitor performance.

2. Assess lifecycle asset management

Continuously assessing and monitoring the configuration of your company's fleet with a focus on vehicle age and fuel type is key. The use of old vehicles is detrimental to the environment through increased GHG emissions and lower fuel efficiency while also translating into higher operational costs through downtime, M&R expenses, and fuel consumption.

Replacing older vehicles with newer models can ease the operational burden and enable the exploration of greener fuels such as natural gas, hydrogen, and biodiesel. Additionally, this boosts worker safety and, subsequently worker satisfaction - ensuring progress in both the "E" and the "S" in ESG. While this may warrant upfront investment in infrastructure, this cost can be partially offset through greater operational efficiency and tax credits and rebates offered in various states for transitioning to electric or renewable energy sources.

3. Optimize route and delivery mechanics

Using historical fleet data, companies can develop tools to optimize their first and last-mile delivery routes and schedules by reducing empty miles, increasing the proportion of FTLs, and providing avenues for shared truckloads for LTL. In fact, this can also be supplemented with real-time tracking of weather and road accidents to allow for quicker re-routing and prevent delays.

As a result, the reduction in miles traveled and fuel consumed translates into cost savings and provides an easy metric to measure and report ESG performance. Simultaneously, it allows fleets to be better aligned with customers' service level requirements and minimizes disruptions in delivery.

4. Select sustainable and compliant suppliers

To ensure environmental and social concerns are accounted for across the entire supply chain, it is imperative to implement relevant governance that ties supplier selection criteria and relationship management to internal sustainability goals. For this, procurement teams must collaborate with existing and prospective suppliers to design a sustainability KPIs scorecard, inclusive of regulatory and legal sustainability requirements, and jointly invest in continuous improvement programs.

This will allow companies to ensure the resilience of their supply chain and their ability to meet sustainability goals while sharing gains with suppliers through increased control over energy and resources. In fact, this also enables suppliers to serve you and you to serve your customers more efficiently. Importantly, increased supply chain resiliency, sustainability metrics, and service efficiency will drive economic and impact value higher.

Footnote

1. The ISSB was formed by the IFRS Foundation to create sustainability standards applicable across geographies and industries to meet the needs of investors, companies, and to facilitate interoperability among stakeholder groups. IFRS - International Sustainability Standards Board

The content of this article is intended to provide a general guide to the subject matter. Specialist advice should be sought about your specific circumstances.