A key component of ethical sourcing is ensuring the health and safety of each worker in the supply chain. Ethical sourcing is an integral component of good governance. Today, this is a necessity and no longer a 'nice to have'.

India is a global sourcing hub thanks to factors like the availability of raw material and skills, labour arbitrage, vendor network and cost effective quality output. Unfortunately, India has been identified as a high-risk country for human rights violations. If you source from India, you should be aware that your supply chain may be subject to critical risks.

While regulatory measures have been initiated by the government over the years to mitigate violations, the scale of the Indian labour market is so vast that these measures take time to show their full impact. The latest regulatory proposal - the newly formulated labour codes, are aimed at further simplifying, modernizing and consolidating numerous overlapping laws to protect workers' rights while also increasing the ease of doing business in India (our detailed analysis of these labour codes can be accessed here and our assessment of their treatment of key business and human rights components can be accessed here).

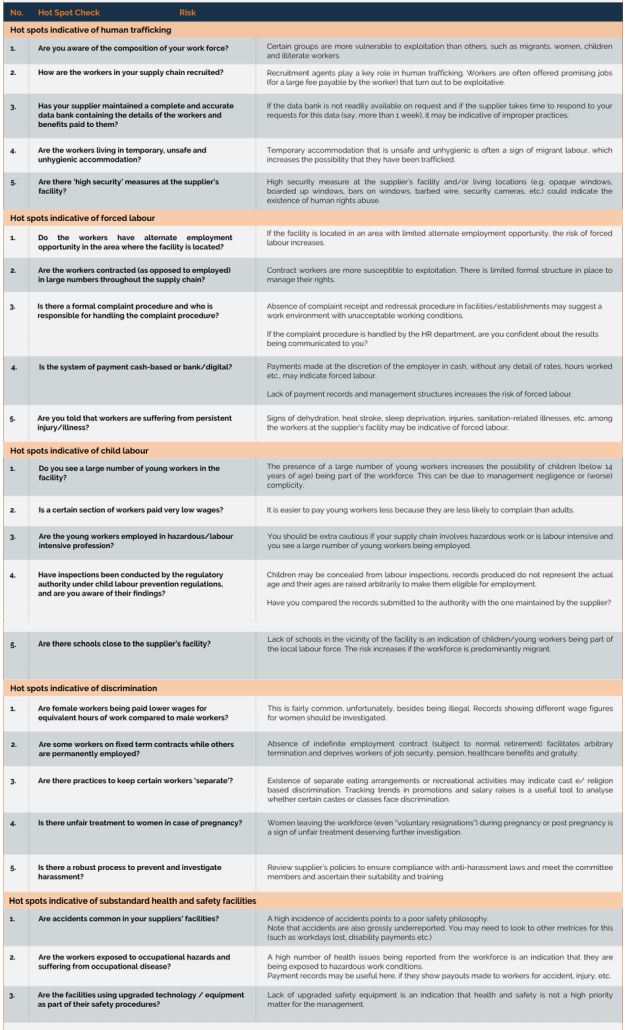

However, the implementation of these codes has been deferred and, at the time of writing this note, no implementation date has been confirmed. In the meanwhile, to aid your efforts towards ethical sourcing, we have compiled a compliance checklist designed to help you move beyond a mere 'check the box' approach, to instead promote responsible business practices by identifying sourcing 'hot spots' in your supply chain.

Try answering these questions with respect to your supply chain in India. This should give you an idea of what risks may exist, and to prioritize mitigation measures.

How can you mitigate these risks?

- Supply chain mapping: Identify risk hot spots in your supply chain using the checklist above as a base and audit practices for compliance with local and international legislations.

- Whistleblowing procedure: Ensure that the organisation has appropriate whistleblowing and non-retaliation procedures that allows workers to report anonymously or to talk with someone other than their supervisor or HR.

- Risk assessment: Conduct a risk assessment to determine which parts of the business and which of your supply chains are most at risk. This should include a review of any existing compliance policies, contractual provisions and supply chain relationships.

- Action: Work with legal counsel to determine what further actions and resources are required to prevent, monitor and mitigate against any risks that are identified in the business and/or its supply chain.

- Contractual risk mitigation: Ensure that supply contracts contain adequate contractual protection including warranties, reporting requirements and audit rights.

- Site inspection: Consider introducing site inspections (both scheduled and spot checks) to the extent not already undertaken.

- Engagement and capability building: Engage with the supplier management to increase awareness and understanding of health and safety risks in the supply chain at all levels.

The content of this article is intended to provide a general guide to the subject matter. Specialist advice should be sought about your specific circumstances.